This info sheet is intended to provide information on the use of wheel chocks to assist in securing vehicles such as trucks from movement while they are parked. Maybe you work in the transportation department, do you know whether your vehicles carry wheel chocks?

REGULATORY REQUIREMENTS

This document may assist in meeting requirements set out by WorkSafeBC relating to:

Unattended Equipment OHS Regulation Part 16.9

The operator of mobile equipment must not leave the controls unattended unless the equipment has been secured against inadvertent movement such as by setting the parking brake, placing the transmission in the manufacturer’s specified park position, and by chocking wheels where necessary.

When they are used properly, wheel chocks are a safe and effective way to prevent the rolling of a parked vehicle.

WARNING! Cribbing (levelling blocks) are not chocks and will NOT secure your vehicle.

In some instances, the ideal wheels may be unavailable to chock, such as when using cribbing (levelling blocks) to level the vehicle. In these situations, the best practice would be to use chocks on at least one of the other wheels that are in contact with the roadway with standard wheel chocks.

CHOOSING THE RIGHT CHOCK

Every vehicle is different. Testing of various wheel chocks is recommended to ensure you have the right chocks for your requirements.

Variables:

- Tire Types

- Load Weights

- Chock Material

- Road Material

CHECKLIST

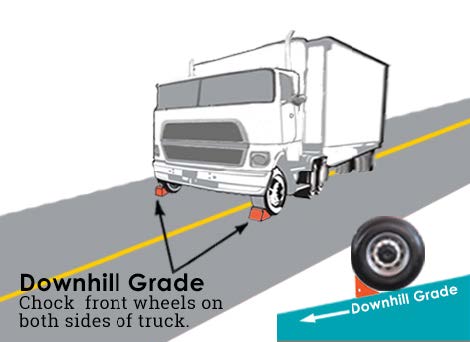

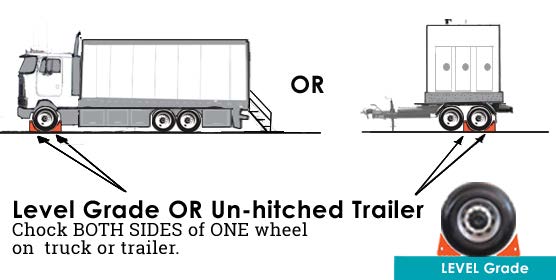

- Whenever feasible, use chocks in pairs (see images above).

- Chock in the direction of the grade (see images above).

- Centre chocks against wheel.

- Towable generator or un-hitched trailer – chock both sides of ONE wheel.

Share Now: