Everything we do – be it building a set, filming, or unloading a truck – takes place in a system that includes the physical and organizational environment and the equipment and tools to perform the task. Ergonomics is the study of how people interact within all these system elements with the goal of optimizing well-being and the system’s performance.

– Gina Vahlas, B.Sc. (Kin), Canadian Certified Professional Ergonomist, Certified Health and Safety Consultant Human Factors Specialist/Ergonomist, Risk Analysis Unit, WorkSafeBC

When well-being and system performance are less than optimal, we experience discomfort, which can reduce our ability to concentrate, be innovative and produce high-quality work. Discomfort can also lead to musculoskeletal injury (MSI), such as sprains and strains.

To prevent an MSI, we need to look at the task, the equipment, and the physical and organizational environment. For example, consider camera operators. How long do they hold a camera for without moving? How much do the cameras weigh? What positions are their bodies in while they hold the cameras?

The ergonomics process includes consultation, risk identification, assessment and control. Education, training and evaluation are also key because workers need to understand MSI risk factors and how to minimize them.

1. Consultation

Consultation takes place throughout the ergonomics process. At a minimum, as stated in the Occupational Health and Safety Regulation 4.53, “…this consultation needs to occur with the joint health and safety committee, as well as workers with signs and symptoms of an MSI and a representative sample of workers who do the job.” It should involve an interdisciplinary team that includes workers (such as members of cast and crew) and managers (such as department heads and directors). Understanding Ergonomics Helps Protect

2. Risk Identification

Employers need to identify factors in the workplace that may expose workers to risks of an MSI. This may include a review of injuries, first-aid records, discomfort surveys, or feedback from workers regarding awkward or inefficient tasks. If no information is available, WorkSafeBC’s Worksheet A can be used to identify MSI risk factors in the job. Once you identify risks, you must determine which are the highest priority for assessment.

3. Risk Assessment

Employers must assess the degree of risk (high, moderate, or low) to the workers in those jobs or tasks where a risk of injury has been identified. Many risk assessment tools are available, including WorkSafeBC’s Worksheet B. Risk assessment will help you decide which factors pose a risk of injury and need to be controlled.

4. Risk Control

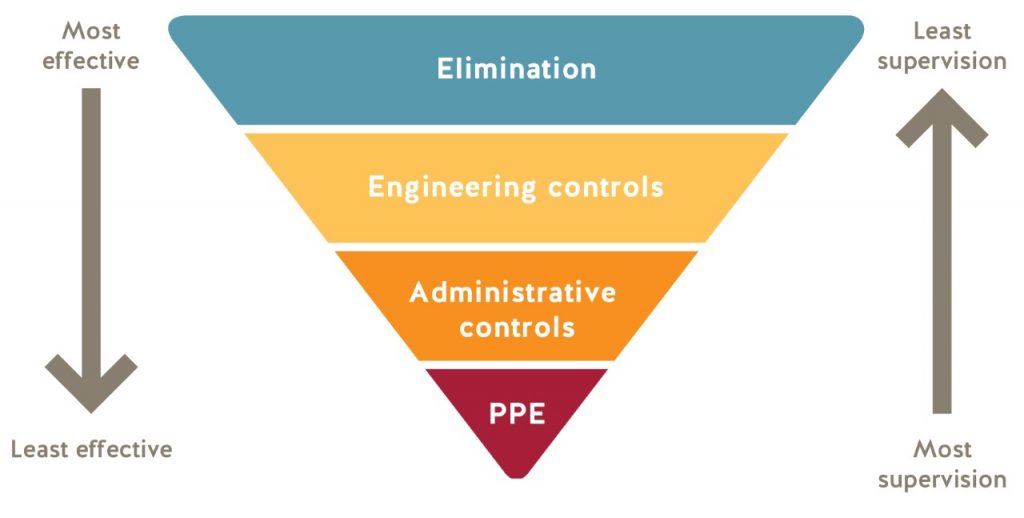

If risk controls are needed, where possible, the employer must eliminate the risk of an MSI. Otherwise, the goal is to minimize the risk. The Hierarchy of Controls diagram below sets out the effectiveness of different risk controls.

Elimination controls, at the top of the hierarchy, are the most effective. An example would be using a forklift to move items rather than relying on manual lifting. Engineering controls include equipment and workstation set-ups that reduce risk. For example, production crew could use carts with terrain-appropriate wheels and adjustable or vertical handles so that each worker can find a handle height that works for them. Camera operators could use dollies, cranes and camera-stabilizers. Administrative controls establish rules and guidelines that mitigate risks, such as work procedures,

scheduling, education, training, and supervision.

Personal protective equipment (PPE) is considered the least effective of controls, requiring the most supervision. PPE is recommended only when elimination, engineering, and administrative controls can’t be applied.

Be sure to consult with workers while selecting controls and test them with workers with different height requirements before implementing them. Also, it’s important to review the viability of proposed changes with workers to ensure other hazards have not been introduced. Evaluate these controls to ensure that they are eliminating or minimizing the risk.

Engaging in the ergonomics process can help to optimize well-being and system performance, improving productivity, quality of work, and comfort, and reducing the risk of injury. For resources on how to reduce the risk of MSIs, visit worksafebc.com/ergonomics or email askanergo@worksafebc.com.

This article was written for our quarterly newsletter, Safety Scene. You can find a link to the full edition below.

Share Now: